The 2025 holiday season is unfolding against a backdrop of rising import tariffs, volatile global supply chains, shifting trade policies, inventory uncertainty, and surging consumer demand. Recent tariff hikes are targeting goods from key manufacturing hubs like China, while lead times are stretched thin due to port congestion and geopolitical unrest. Moreover, the situation is further intensified by rising U.S. tariffs on Chinese imports, ongoing disruptions in the Red Sea impacting U.K. and EU-bound shipments, and labor unrest across parts of Europe and Southeast Asia.

A striking example is the October 2024 dockworkers’ strike at major U.S. ports, which disrupted the flow of holiday goods and threatened price hikes on essentials such as food, toys, and Christmas trees. Though swiftly resolved, the incident highlighted how even brief disruptions can ripple across the supply chain during peak retail months.

At Delaplex, our supply chain solutions are purpose-built to help businesses stay agile, resilient, and competitive, even in the face of holiday disruptions and trade tensions.

Factors Disrupting the Holiday Supply Chain

Holiday Demand Spike

During holiday times, retail sales often rise, placing enormous pressure on inventory management, staffing, and fulfillment operations. Additionally, promotions, social trends, and weather shifts can affect demand unexpectedly.

Inventory Inflexibility

Stockpiling to beat tariff deadlines often leads to an overstock of low-demand SKUs or cash flow strain, particularly when holiday demand proves unpredictable.

Port Congestion

The holiday season naturally slows down transit times. Further, tariff-induced import surges intensify pressure on already-congested ports.

On April 9, 2025, the U.S. imposed a staggering 145% tariff on Chinese imports that was later reduced to 30% for a provisional six-month period after bilateral talks. However, the disrupted seasonal supply chain and holiday product lines were already hit hard.

Overstocking and Understocking

Retailers risk overstocking unpopular items or understocking high-demand products, leading to lost sales or excess inventory.

Retailer Margin Pressure

As transportation costs, duties, and labor expenses rise, maintaining profitability becomes more challenging. Seasonal discounts and free shipping expectations clash with growing operational overheads.

The Ripple Effect of Seasonal Setbacks

Holiday disruptions aren’t just seasonal inconveniences; they’re compounding risks that can spiral into:

- Severe revenue loss from missed sales windows, stockouts, or overstocked dead inventory.

- Reputational damage caused by delayed deliveries, order errors, and broken customer promises.

- Missed opportunities where competitors seize mindshare and wallet share through better readiness.

- Operational breakdowns due to overstretched supply chain processes and manual bottlenecks.

- Poor customer retention as buyers switch to brands with faster fulfillment and better availability

- Increased operating costs driven by expedited shipping, surge pricing, and overtime staffing.

- Forecasting inaccuracy that distorts performance metrics and affects next year’s planning.

- Inefficient resource allocation across inventory, warehousing, and labor due to last-minute pivots.

- Disrupted analytics & reporting from inconsistent or fragmented supply chain data.

- Increased cyber and compliance risks from scaling up under insecure or under-regulated systems.

How Delaplex Helps You Turn Disruption into Competitive Advantage

At Delaplex, our solutions are purpose-built to help businesses stay agile, resilient, and competitive, even in the face of holiday disruptions and trade tensions.

Tariff Inventory Optimization

We empower businesses to stay ahead of tariff shocks with predictive, AI-driven inventory optimization. By leveraging advanced simulations, digital twins, and data analytics, we help clients model cost fluctuations, prioritize high-impact SKUs, and implement pre-order and staging strategies.

Result: Smarter planning and sourcing decisions reduce tariff-related expenses and protect profit margins during trade shifts.

Real-Time Inventory Intelligence

We empower businesses to stay ahead of tariff shocks with predictive, AI-driven inventory optimization. Further, by leveraging advanced simulations, digital twins, and data analytics, we help clients model cost fluctuations, prioritize high-impact SKUs, and implement pre-order and staging strategies.

Result: Achieve reduction in stockouts and improvement in sell-through rate through smarter, real-time inventory visibility.

Supply Chain Risk Mitigation Suite

We equip businesses with a comprehensive risk mitigation process that simulates the impact of trade disruptions like tariff hikes, freight delays, or supplier breakdowns. Our advanced planning capabilities allow clients to proactively model scenarios, ranging from port congestion to sourcing shifts, and prepare mitigation strategies in advance. Through intelligent automation, we recommend alternative suppliers, reroute logistics flows, and optimize sourcing decisions using tariff-inclusive cost modeling.

Result: Rapid disruption response and stronger supply chain resilience amid geopolitical volatility.

Margin Intelligence & Dynamic Pricing

Our real-time margin intelligence tools track SKU-level profitability, especially for tariff-sensitive items, and dynamically adjust pricing using AI-driven algorithms that consider demand elasticity, market trends, and cost fluctuations. With smart guardrails around promotions, businesses can avoid underpricing and ensure every discount protects bottom-line goals.

Result: Achieve improvement in profit retention during tariff and holiday shocks.

Strategic Workforce & Labor Planning

As global enterprises respond to tariff pressures by relocating operations to new geographies, labor planning becomes a strategic lever for long-term success. Our strategic labor planning services help you identify the right mix of roles and capabilities required in new locations, while our compensation modeling ensures competitive and sustainable pay structures aligned with local labor markets. Combined with operational planning, we help you forecast seasonal staffing needs, optimize labor allocation, and build flexible talent strategies that scale with demand surges and market shifts.

Result: Ensure business continuity, minimize workforce disruptions, and align labor strategies with evolving supply chain footprints and global trade dynamics.

How to Survive the Dual Threat of Holiday Disruptions and Trade Tensions

As we enter a high-risk season, where tariffs and holiday demand collide, inaction is not an option. The businesses that will thrive this season are the ones that act early, plan intelligently, and leverage data at every decision point.

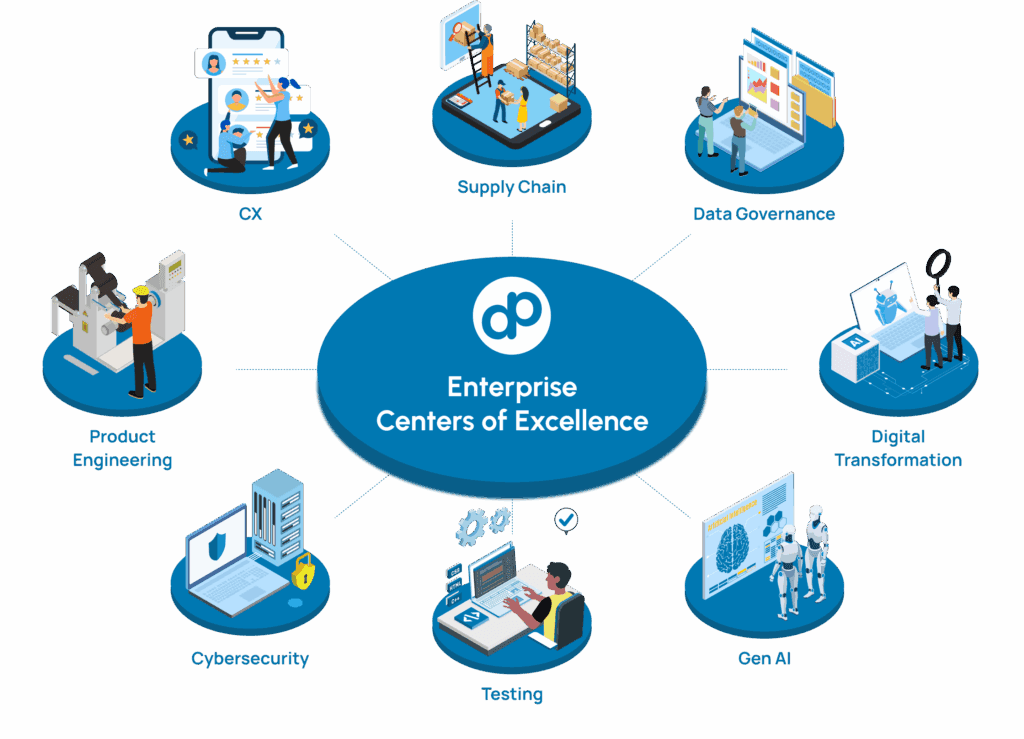

At Delaplex, we firmly believe that agility is the currency of today’s dynamic markets, while resilience is the revenue that sustains long-term success. Our tailored digital supply chain solutions help you plan smarter, pivot faster, and perform stronger. Complementing these capabilities, our Centers of Excellence bring deep domain expertise, scalable automation, and cutting-edge technologies like AI, digital twins, and advanced analytics. Together, clients are empowered to turn uncertainty into opportunity, protect profitability, and outperform the market.

Contact us today to build a supply chain that’s ready for whatever comes next.